Category — Equipment

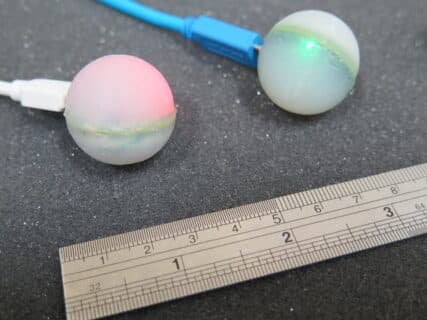

25 mm Impact Recording Device, by Techmark Inc.

Commercial Launch: 2020

While those working the potato industry have had access to the impact recording device for years, it was always sized for larger varieties. The device is meant to help reduce incidents where potatoes may get bruised during the production process. Growers now have access to the 25 mm Impact Recording Device which is made for smaller potato varieties.

The 25 mm Impact Recording Device is meant for fingerling and creamer sized potatoes. It evaluates and identifies areas in the handling of potatoes that may be causing mechanical damage, to reduce damage during the handling processes to help growers identify and reduce overall waste.

InteliRain Micro-Precision Irrigation (MPI) System, by InteliRain Inc.

Commercial Launch: June 2022

With water being a limited resource for some potato growers, ways to reduce usage while still giving spuds the water they need is paramount. The InteliRain Micro-Precision Irrigation (MPI) System is a fully automated pivot irrigation solution that reduces water usage by up to 34 per cent and increases yields by up to 17 per cent.

It has multi-spectral robotic sensors mounted onto each span of the pivot that scans the field ahead and behind of the pivot, creating real time field data. Data is collected using the offline LoRa communication to wirelessly transmit sensor data to an on-site computer.

Using real-time sensor and weather data, the system generates a nozzle-specific watering prescription suited to the current watering needs of the crop. It uses machine learning to account for the unique characteristics of each micro-zone within the potato field, allowing for precise soil moisture predictions. The nozzle-specific prescriptions are wirelessly transmitted to each span of the pivot automatically. It also controls the speed of the pivot according to sensor data, wind drift and evaporation losses to maximizing watering efficiency.

John Deere 8RX Four-Track Tractor wide track kit, by John Deere

Commercial Launch: Jan. 4, 2023

Driving a tractor down potato rows isn’t always easy, as you don’t want to drive on top of a hill and damage the spuds growing in it. The John Deere 8RX Four-Track Tractor is a fixed-frame tractor with four tracks designed for potato row spacing. There’s 132-inch, 136-inch, 144-inch and 152-inch track spacing available, allowing the machine to straddle four rows on a 33-inch, 34-inch, 36-inch, or 38-inch spacing. The rubber tracks are available in 16.5-inch or 18-inch track widths for row-crop applications or can be equipped with 24-inch and 30-inch tracks for maximum flotation.

The wider track spacing allows more room to maneuver the machine over the crop during harvest, reducing the possibility of bruise on harvested potatoes. The steerable front tracks of the tractor have the same turning radius as a machine with a set of duals, but only make one track instead of two. It also has a 25 per cent longer track footprint compared to a two-track machine, causing reduced compaction, increased traction, and stability on side hills.

Picketa Systems’ LENS, by Picketa Systems Inc.

Commercial Launch: Nov. 15, 2020

The faster a deficiency in nutrients is diagnosed on a potato plant, the faster growers can treat the plant and increase they chance at higher yields. The Picketa Systems LENS is a near real-time plant tissue analysis tool that allows agronomist and growers to do petiole nutrient analysis without the need for laboratories, eliminating long transit delays and the need for highly trained personnel.

Picketa’s product requires for a petiole sample to be taken in field. It’s then brought back to an office where the plant is scanned into Picketa’s computer program, which instantaneously reveals potato nutrient levels. It uses an optical sensor used to scan leaf samples and then a machine-learning engine and cloud infrastructure are used to interpret the data gathered by the optical sensor.

Seed Sensing Technology, by Bluefield Seeding Solutions Inc.

Commercial Launch: Dec. 1, 2022

Seeding is an important part of the potato production cycle and knowing that your seed has been properly planted can make all the difference. Seed Sensing Technology allows potato growers to know their seed placement performance without having to dig them up by hand. It creates the opportunity for greater efficiencies, productivity, and better overall financial results throughout the field.

It uses Bluefield Seeding Solutions Inc.’s press wheels that sense the contact with each seed piece while the seed is being locked in place by the press wheels during planting. This allows the seed piece to become stationary in the furrow. It gives real time feedback of the actual seed placement on a per row basis, allowing the grower to maximize planter performance and planting speed. The seeding data recorded includes total and per row data for total planted, number of ideal placements, number of less-than-ideal placements, number of misses, and number of doubles on a per field basis.