In our spring production webinar, Dr. Mark Pavek explained how much of a difference in-row spacing, between row spacing, and row direction can make on final crop yield, and how to get those factors right.

As you prepare to head out into the fields for potato planting this spring, there are a lot of things to consider. What varieties should you grow? When is the best time to turn on irrigation? What pests and disease will need to be managed? While those are key questions, exactly how you arrange your plants can also have a significant impact on your crop’s final outcome.

In our spring production webinar held March 1, 2024, Spud Smart hosted Dr. Mark Pavek, a potato research agronomist and professor within the Department of Horticulture at Washington State University.

Pavek has conducted significant research into how best to spatially arrange potatoes for optimized growth. As he explains it, the key is to position plants so they optimize tuber size profile, economic return, and collection of solar radiation. By choosing the proper row width, in-row spacing and row orientation, growers can use their planters to optimize whole plant photosynthesis and profit.

In-row and Row Spacing

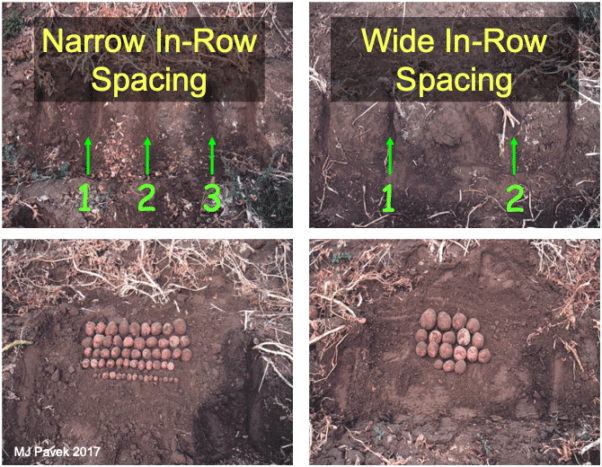

The easiest factor to adjust in the arrangement of potato plants is in-row spacing. Manipulating in-row spacing is very effective at changing the size profile and total number of potatoes produced per foot of row. More spacing between plants means fewer total spuds but significantly bigger size per tuber. Note: consistency of emergence is even more critical than consistency of seed spacing. Optimize every planting factor to ensure the seeds that go into the ground get up and growing successfully.

While in-row spacing is easier to control, row width needs somewhat more complicated consideration.

Back in the early days of potato production, row width was set by the space between the two horses used to pull planting and harvesting equipment (typically 34-inch to 38-inch). Row width since then has often also tended towards ‘prioritizing the horses or equipment design over the plants’.

“Somewhere along the way, when they designed equipment to do this, they may have just picked a row width that worked for [equipment manufacturers] and growers adapted to that,” Pavek said in the webinar. “And maybe it wasn’t the most economically feasible row width, but it’s the one that worked with their equipment.”

Pavek disagreed with the equipment-focused way of thinking, so he conducted research on standard and optimized widths.

“We need to always question what we’re doing,” he said. “Can we improve it?”

In fact, he found that row width varies across the globe. In the U.S. and Canada, it’s typically in the 32 to 38-inch range, with variation depending on region, irrigation, season length and potato type. (Canada 34 to 38-inch; Columbia Basin: 22-inch and 34-inch; Oregon 34-inch and 36-inch; California 32-inch and 34-inch; Idaho 34-inch and 36-inch but beds with 26-inch or 18-inch; seed and specialty crops 17-inch to 36-inch). In the UK, spacing varied between 28-inch and 30-inch in the 1960s, but expanded to 36-inch in the 1970s. Today, rather than a 36-inch to 36-inch consistent spacing, many growers use 34-inch to 38-inch variable spacing to accommodate wide tires. Continental Europe tends towards a 30-inch spacing with skinny tires.

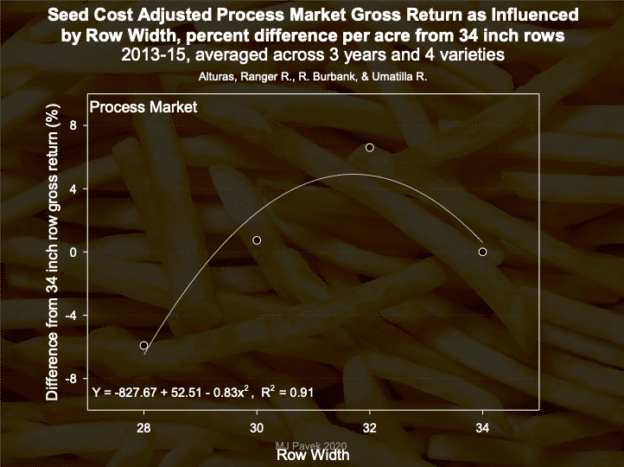

What can one expect if rows are moved closer together? Pavek and his team planted nine varieties into trial plots at the WSU research farm near Othello, Washington each year between 2011 and 2015. The plots were grown at full season, unlimited irrigation with consistent 10-inch in-row spacing. The plots were grown at 30, 32, 34, and 36-inch spacing in 2011 and 2012, then realizing 36-inch was too wide for the Columbia Basin, the team switched to 28, 30, 32 and 34-inch spacing in 2013-2015.

The trial determined several key findings. First, as rows got closer together, vines grew taller. With more competition, they had to grow longer to reach sunlight. The important question is whether this growth was wasted energy that decreased total crop yield.

Average tuber weight stayed fairly consistent (Pavek says the slightly lower tuber weights seen in the 28-inch rows were based on irrigation starvation: the team was irrigating for a 34-inch row spacing, but more tightly packed rows need more water).

While average tuber weight didn’t change, what did change was tuber numbers per plant.

Tuber count “went from middle 7s [about 7.3] to all the way up to 9.0 just by moving our rows farther apart. When you move your rows farther apart, plants have less competition, they feel like they can do more, so they increase the tuber number,” Pavek said.

Yet, the total number of tubers harvested per acre remained consistent regardless of spacing, Pavek found.

“At harvest, the tuber number that came over the belt was essentially unchanged.”

Likewise, green tuber numbers were unchanged by row spacing.

In terms of total and market yields, the results varied by variety. Averaged across varieties, Pavek said: “We see that total yield peaks somewhere between 32-inch and 30-inch row width.”

While the lower results at the tighter end of planting was likely due to water starvation, the notable drop is at the high end of spacing: at 34-inch spacing, yield was notably limited by the number of plants.

The number that matters most, of course, is measured in dollars and cents. When the additional costs of planting more rows per acre (seed, fuel, equipment depreciation and labour) were factored in, Pavek’s team found returns peaked around 32-inch.

What does that mean, at least for Columbia Basin growers?

“We recommend growers in the Columbia Basin plant at 32-inch,” says Pavek.

To the many who are still on 34-inch spacing, he acknowledged: “It’s hard to change especially when you have equipment based on 34-inch. I recommend if growers want to change, wait for your equipment to depreciate out and then your next round of equipment, get it set up for 32-inch.”

Tighter spacing could mean following Europe’s lead on skinny tires with inset rear tires on self-propelled harvesters in some fields. If that doesn’t work, growers might consider windrowing, Pavek said, to allow tighter rows and skinnier tires without risk of bruising.

Pavek provided this list of key takeaways regarding row width:

Are you ever concerned your potatoes are too dry during the season?

- A larger plant population may require more water

How well does your canopy close the rows on 36-inch?

- Would closer rows shade the ground better, reducing evaporation?

Higher plant populations per acre generally get you higher yields

- But seed costs increase, and water needs may increase, so higher economic returns are not a guarantee.

It is possible that some combination of row width and in-row spacing different from the one you use now may being better economic return without requiring more irrigation.

- Row width research is needed in your growing region.

Row Orientation

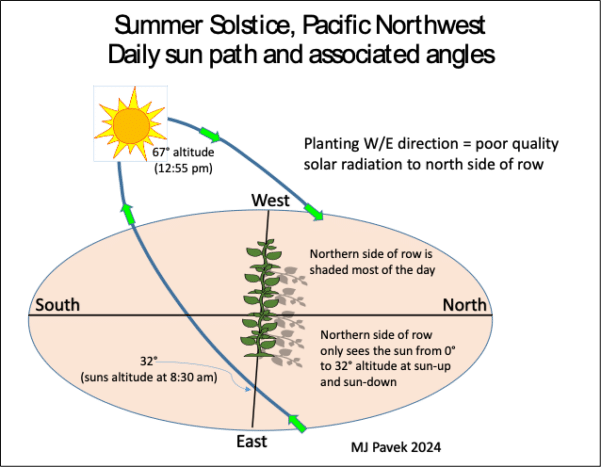

Pavek and his team conducted a separate study into whether row orientation matters. While slope, field shape and obstructions can sometimes limit choices for planting direction, those growers who are able should consider their directional options.

Across six field years (2015-2020), Pavek and his team planted four russet potato varieties in north-south, northwest-southeast, northeast-southwest and west-east orientations, assessing yield and economic return.

“Emerged potato plants in a row are bunched up like a hedge. Before rows close, you’re getting a lot of your sunlight on each side of the row and on top,” he explained. Since the plant uses that sunlight to create energy, more sunlight and less shade means more energy to put towards growth and ultimate yield.

So, the team measured the amount of sunlight on both sides and the top of each row. All row with some version of north/south orientation (NS, NW/SE, NE/SW), showed dramatically more sunlight capture across the entire plant than the east-west orientation, which had good light collection on the south side of the row but low light collection on the north side.

How does this translate to yield?

“There was no significant difference across these different directions in average tuber weight,” Pavek said.

However, when he looked at total and market yield, there was a clear cost to one planting direction.

“Guess what? The row orientation with the most shadow throughout the day, east/west, had a lower market and total yield and the others were all about the same when we took statistics into account. Anything with north or south in the direction did better than just east to west, and that was across all varieties.”

When he applied economics to the calculation, east to west delivered the lowest gross returns — 15 per cent lower than the north-south comparable — across all varieties.

“Remember, when you’re in a canopy and you’re a leaf looking for light, any place light can get in, it’s going to get in. That’s important. That’s why direction of planting is not important only before the rows close, but even after your canopy closes the rows, you’re still getting light in. It does make a difference,” he said.

“Solar radiation is free and only a fraction of it is captured by crops. Manipulating planting direction to improve the efficiency with which crops capture sunlight is a promising strategy for improving crop productivity.”

Have additional questions about this webinar? Want to share comments? Would you be interested in sharing your knowledge via a webinar? We’d love to hear from you. Reach out to [email protected].

Watch the entire webinar now! https://www.youtube.com/watch?v=m5lIXljINa8