Potato seed treating usually involves setting the application rate. It’s set for an estimated average flow rate of seed potatoes through the treater. In practice, that potato flow rate will vary — sometimes by quite a bit. This leaves potential for poorly treated seed reaching the field. To avoid this, some operators will err on the side of caution and set the chemical application a little higher than necessary. While this reduces risks in the field, it also leads to waste and higher costs.

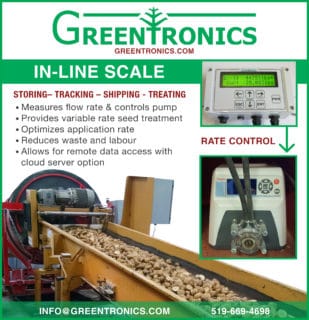

To solve this problem, growers can install a scale from Greentronics in the conveyor ahead of the treater. The scale can be equipped to output a signal proportional to the flow rate over the scale. This output becomes the input for the chemical application pump. With this connected, the pump will now apply chemical according to the flow rate measured by the scale. The grower will have better assurance that chemicals are being applied at the optimal rates to provide protection to the crop in storage and in the field. This offers greater uniformity in chemical application and reduced waste and cost.

Treatment of harvested potatoes flowing into storage is becoming more common. The scale with pump control output will work equally well for variable rate application of storage related chemicals.

Loading trucks, inventory tracking, and recording field and variety totals continue to be standard features available on every scale.

Traceability reporting becomes possible by using the scale for generating basic storage maps.

Remote data access is optionally available to customers who require convenient access to scale data while away from the farm, and Greentronics offers a cloud server option. Here, any android device with a data plan can be connected to the scale at the storage to enable wireless data upload to the cloud server. Greentronics’ data upload app and custom software will capture and process data automatically. Greentronics’ customers receive secure access to the server where they can view and download reports and charts detailing the movement of their potatoes over time.

Further details are available from Greentronics’ dealers and direct from Greentronics. Please visit www.greentronics.com to find a dealer near you or complete the contact form on our web site.