[deck]Mike Thornton and Paul Bethke share their views on sugar ends and stem-end chip defect.[/deck]

SUGAR ENDS AND stem-end chip defect are tuber disorders affecting product quality of processing and chipping potatoes, respectively. The environmental stresses causing the disorders occur during the growing season, but tubers appear asymptomatic until harvest or later in storage. Although there are many similarities between the two disorders, there are also some key differences.

To understand the factors causing sugar ends and stem-end chip defect as well as management practices to reduce the development risk of these disorders, Spud Smart sought input from industry experts Mike Thornton, a professor of plant science at the University of Idaho, and Paul Bethke, a scientist with the USDA Agricultural Research Service and an associate professor at the University of Wisconsin.

SUGAR END DEVELOPMENT

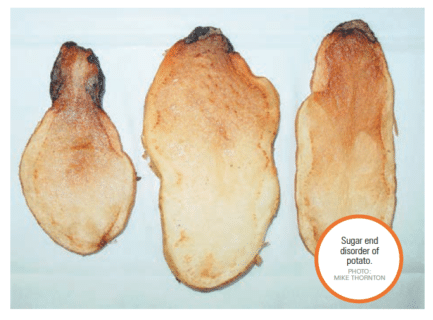

Sugar end disorder is caused by the accumulation of high levels of reducing sugars (glucose and fructose) at one end of the tuber, usually the basal (stem) end, but can also develop in the apical (bud) end, in response to stress.

This physiological disorder seriously affects the product quality of processing potatoes. For example, upon frying, the tuber tissue at one end of a French fry — the end with low starch and high reducing sugars — turns brown or black.

For processing potato growers, a worst-case scenario is rejection of the crop by the processor. Processors also experience losses due to product trimming and quality downgrades.

The stresses causing sugar ends, also known as dark ends, jelly ends, translucent ends or glassy ends, usually occur early in the growing season during tuber initiation and early tuber bulking. Potatoes appear asymptomatic until exposed to colder temperatures — 10 C or cooler — in the field or in storage, says Thornton.

Normally, a potato plant makes sugars in the leaves via photosynthesis, which is translocated downward to developing tubers. Under normal growing conditions, most of the sucrose is converted into starch in the tuber, however, under stressful conditions starch production is not favoured and carbohydrates (starch and sugars) remain in the form of sucrose.

“When there is a stressful situation, particularly high soil temperatures, the potato plant will struggle with that last step to convert those sugars to starch in the tuber,” Thornton says. “You can get an accumulation of sugars in one end, usually in the tuber’s stem end, and you don’t see it unless it’s really severe visually when you cut the potato open.”

High soil temperatures during early tuber development causes sugar ends. “Basically, soil temperatures in the mid-70s [around 23 C and higher] when tubers are developing is where the potato starts to struggle to form starch,” says Thornton.

High temperatures alone can cause sugar ends; however, inadequate soil moisture can exacerbate the disorder.

The tuber’s membranes are damaged by the environmental stress and they lose the ability to compartmentalize the various biochemical constituents, explains Thornton. This damage allows reactions to occur that produce reducing sugars.

“Potatoes don’t lie and will show when they are stressed. If the sugar end symptom is expressed at the tuber’s stem end that indicates the stress happened early in the growing season,” he says.

Conditions favourable for sugar end development include drought conditions, the initiation of hot weather coinciding with tuber initiation and early tuber bulking and continued warm day and night temperatures for many weeks, says Thornton.

The end of the potato with the higher sugars will fry darker resulting in a gradient from a light golden colour to dark brown. The industry defines sugar ends as French fries with a predominant colour of No. 3 or darker based on the Munsell USDA Frozen French Fry Standard.

Factors that affect tuber development timing and plant canopy growth with respect to heat or water stress onset can affect the incidence of sugar end disorder, says Thornton. Planting date, field location, crop rotation, soil type, fertility, soil compaction, soil moisture, irrigation and variety all play a role in the development and incidence of sugar end disorder.

PLANTING DATE

Planting date can be altered to lower the risk of sugar end development in situations where high temperatures usually coincide with the beginning of tuber development.

“Any time in the development of a tuber up to the size of a hen’s egg is when those tubers are most susceptible to sugar end development if there is high temperature stress,” says Thornton.

“If you’re in a region where temperatures tend to do that, say, in mid-June, if you can get the plants up and established so that the canopy or vine development is shading the soil, you’ve got the benefit of those cooler soil temperatures to help reduce sugar end development.”

However, if growers plant too early and a poor stand develops due to seed decay, creating gaps in the canopy, soil temperatures may be high in those areas of the field.

“In that case, early planting could actually hurt you,” says Thornton. “You don’t want to plant so early that you have a poor stand. You want to plant early enough, in the proper window, so you get good plant development for when the hot temperatures come.”

CROP ROTATION, SOIL COMPACTION AND FERTILITY MANAGEMENT

Decreasing the incidence of sugar ends really comes down to following the practices growers know are good for potato growth, Thornton says. For example, planting potatoes following wheat, or other cereal crop, rather than a low-residue crop (i.e. sugar beets), which won’t return residue to the soil and may require heavy machinery that causes soil compaction.

“You’d expect the choice to follow wheat, or other cereal crop, would give you the best shot at avoiding sugar ends because that’s the best conditions for water infiltration and good plant development,” says Thornton.

Soil compaction affects how well water infiltrates the soil and how much reaches the area where roots are developing. Soil compaction can also restrict the extent of root development creating a smaller zone from which the plant can pull water.

“Situations develop where the plant is basically lacking water even though the soil is moist in a general sense — you just don’t have the root system to pull moisture out of the field,” says Thornton.

Soil type also plays a role in a crop’s susceptibility to sugar end development. In general, a medium-textured soil, such as silt loam or sandy loam, tends to have less sugar end development than sandy soils, which warm up quicker and can be warmer during the growing season. However, good plant development, shading, and irrigation practices can offset higher soil temperatures due to soil type, adds Thornton.

Crop rotation is also important because diseases such as Verticillium wilt and Rhizoctonia, which affect the root system, can contribute to sugar end development by stressing the plant, limiting the rooting area and the plant’s ability to extract moisture and nutrients. These diseases affect the root system during a key period when the plant is growing and requires lots of nutrients and water, which also coincides with hot temperatures.

Fertility management can also play a role in decreasing sugar end incidence because nutrient availability helps drive plant development, which in turn affects soil shade and soil temperature.

“You need adequate nutrients, but you can also have too much. You can get into a situation where there is an imbalance between the growth of the leaves, which are demanding water, and the growth of the roots, which supply the water,” says Thornton.

Nitrogen is such a case as it helps leaf and vine development but does little for root development. “You can have a really big plant that’s demanding a lot of water, but not a larger root system to supply that demand,” he says. Thus, the crop is water-stressed even though there appears to be adequate soil moisture.

IRRIGATION MANAGEMENT

Early tuber development is a critical time for irrigation management. Vines and tubers are growing fast during this stage. When temperatures are increasing, growers can fall behind on soil moisture management and irrigation scheduling.

During this period of rapid plant growth, the tuber is at its most susceptible to sugar end development. Thornton recommends growers keep a close eye on the crop and soil moisture management. Light, frequent, sprinkler irrigation applications during hot periods can have a cooling effect on the soil, as long as growers don’t get behind on the overall soil moisture availability.

“If you’re irrigating so frequently that you’re losing a lot of the water you’re applying to evaporation, and you’re not recharging the full soil profile, then those light, frequent, irrigation applications are not going to help you — and they may hurt you,” says Thornton.

THE ROLE OF VARIETY

Variety also plays an important role in sugar end development. Both Russet Burbank and Ranger Russet are susceptible to the disorder, says Thornton. “Russet Burbank is the poster child for this disorder. It requires very uniform management, particularly on the nutrient and water availability side. Burbank is a variety you can’t afford to make management mistakes with if you have a hot season,” he says.

Many of the newer russet varieties, such as Clearwater Russet which is gaining rapid adoption in the Western United States, with resistance to sugar development in storage also tend not to develop sugars when stressed in the field, says Thornton.

Other new varieties that tend to be low sugar-developing are also resistant to sugar ends. The varieties that don’t go off-shape when stressed (by developing knobs or dumbbell shapes), also tend to have a lower incidence of sugar ends.

“There’s an association between tuber shape and this physiological disorder that’s caused by high sugar accumulation,” says Thornton.

PLANT MATURITY

Another factor affecting sugar end development recently identified by researchers is plant maturity. When a potato crop begins to naturally decline and senesce, and the soil becomes heated by the sun late in the season, potatoes can become over-mature if they sit under dead vines for a long time.

“That will tend to aggravate sugar end development,” says Thornton. “Once again, keeping a good, healthy, canopy up until vine kill, and not allowing the crop to die and the tubers to sit for a long period of time under dead vines is another key factor for avoiding sugar ends.”

According to Thornton, another important point about the development of sugar ends is the effect of stress on the tubers is cumulative, meaning a little stress on the crop may cause only a slight incidence of the disorder whereas a lot of stress increases the disorder’s incidence. Also, a long period of stress is going to cause more damage than a shorter one. In addition, the higher the soil temperature, the less it cools at night and the longer that period lasts, the greater the risk of sugar ends.

FOCUS ON LIMITING DECAY

Once tubers develop sugar ends, the disorder is not reversible — those tubers won’t recover. Storing potatoes at warmer temperatures early in the storage season will not convert sugar back to starch or release sugars through respiration. Additionally, holding the crop at a warmer temperature will not decrease the level of sugar ends in the stored crop, says Thornton.

Rather, growers should focus on limiting decay due to jelly end rot in storage and preserving an acceptable colour for the potatoes not affected by sugar ends.

“It’s just a matter of good management practices. Make sure you have an adequate wound healing period, holding those potatoes at the recommended temperature of 50 to 55 F (10 to 13 C) for wound healing and ramping them down slowly by half a degree Fahrenheit or less per day to the holding temperature,” says Thornton.

“Don’t go down below the holding temperature for the market that crop is intended for. It’s really critical not to expose processing potatoes to cold temperatures because that will aggravate sugars overall, but even more in a stressed crop.”

Growers should also monitor the crop closely because potatoes with jelly end rot are susceptible to pathogen infection through the damaged tissues.

STEM-END CHIP DEFECT IN CHIPPING POTATOES

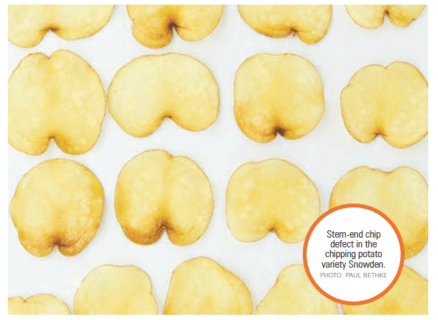

There are many similarities between sugar end disorder and stem-end chip defect (SECD), says Bethke. This defect shows up on the basal (stem) end of the tuber and is characterized by post-fry discolouration.

While sugar end disorder is graded by colour, SECD is graded by severity. In the mildest cases, SECD causes discolouration tracing the vasculature at the potato’s stem end. As the defect severity worsens, the line of discolouration broadens out preferentially toward the periphery of the tuber, eventually moving inside the vasculature, but still forming the shape of an arc, smile or mustache, depending on how the tuber slice is cut and the vasculature is laid out, says Bethke.

Much like sugar end disorder, the presence of SECD is not apparent until harvest or later. “Potato chip growers routinely do some test digs prior to harvest,” says Bethke. “They fry up some slices and everything looks beautiful. The day of harvest things still might look okay, or there may be some little defects showing up, but it may be up to a month after harvest when a grower discovers they’ve got a bin full of potatoes that really aren’t looking that good.”

Generally, the defect severity increases for the first month or two after harvest, regardless of variety. However, unlike sugar end disorder, with some varieties the defect severity will slowly start to improve.

“If the defects weren’t too bad you can sometimes wait them out. This is something you don’t really see with sugar end disorder,” says Bethke. However, if the defects are severe at harvest or shortly after harvest, Bethke warns those potatoes may not recover.

WARM NIGHTTIME TEMPERATURES

Bethke started working on SECD about 12 years ago when the disorder became a large problem for Upper Midwest growers, in particular. At that time, SECD was causing processors to reject lots and growers were having difficult conversations with their customers.

Back then, there were no clear answers to what caused the defect, what varieties were susceptible or tolerant, or what could be done in terms of management. What Bethke has learned over the past decade or so is the disorder has many causes.

“It’s not just one thing you can point to and say if that happens then you’re going to have this problem,” he says. However, researchers have identified the most important factor triggering the defect: warm temperatures, particularly at night.

“The field data we’ve seen as well as some experimental work we’ve done suggests it’s actually warm temperatures at night more than during the day that contribute to stem-end chip defect formation,” says Bethke.

“This is part of the reason why defects are more prevalent in areas farther south or where the environment is more humid, because you can capture heat in the humid nighttime air.”

Similar to sugar ends, SECD is more likely to occur in potatoes infected with Verticillium dahliae. “Verticillium can plug up the tuber’s vasculature, which may prevent leaves from cooling down during the day,” says Bethke.

Other traumas to a potato field that can increase a crop’s risk of SECD include defoliation due to hail or insects. “Fields hit by hail had severe stem-end chip defect,” he says. Also, insect swarms that really knock the plant canopy back as they move through a field can cause SECD, he adds.

To simulate these conditions in a laboratory, Bethke shut down the photosynthetic process by growing potato plants in low light for a week, which increased the severity of SECD in the tubers.

“Lots of things can cause the defect. That’s one of the reasons it has been difficult to predict, but environmental stress seems to be the biggest factor, in general,” he says.

So far, crop management hasn’t been the answer for decreasing the incidence of SECD. Trials studying planting depth and planting date haven’t provided solid solutions. One thing that is clear is the damage from stress results in a cumulative effect on defect severity. “In the case of nighttime temperature, [defect severity] seems to be cumulative — seven episodes over the course of the summer is worse than three episodes.”

VARIETY CHOICE

Currently, variety choice is the best option to manage SECD. Growers who have experienced problems with SECD can select varieties that are less susceptible to defect formation, if that is an option for them, says Bethke.

For example, Snowden is a long-time, popular, chipping potato variety, which is also susceptible to SECD, as is the variety Atlantic. “One of the reasons you might not want to store Atlantic is it can get really beautiful defects,” says Bethke.

The variety Lamoka has shown a little more tolerance to SECD than Snowden. However, some varieties, such as Manistee and Niagara have shown good resistance to stem-end chip defect. Although less studied, data suggests the variety Nicolet has some resistance, as does the variety Pike, says Bethke.

One other area Bethke is exploring to help solve the SECD problem is biotech potatoes. He’s worked on studies where the vacuolar invertase gene in potato has been silenced. He found when the gene is suppressed, the SECD severity is reduced in chipping potatoes. Sugar end disorder was also decreased when the invertase gene was suppressed.

“This technology can offer improvement here. Whether or not it’s the right solution — that’s a whole different question. However, there’s definitely potential there,” says Bethke.

MANAGING SECD IN STORAGE

Because the environmental conditions favouring SECD don’t occur every year and, therefore, not every year is a SECD year, even growers who have seen a lot of the defect on their farms have a hard time predicting how bad or how good the crop is going to be coming out of storage, which can make managing storage of the crop difficult.

However, once the crop is in storage, potatoes with SECD could improve over time, says Bethke. He recommends growers follow standard, good management practices for chipping potatoes.

“There’s some hope in that after a month or two of getting worse, the defect tends to slowly get better. Manage your potatoes as best you can during that period. This is just opinion, not science, but any other stresses you impose in storage that cause potatoes to go off-colour or cause sugar profiles to go up, it’s probably going to exacerbate the difficulties you have with stem-end chip defect,” he says.

“It’s the same management strategy you use for your very best potatoes — lots of fresh air, don’t cool them too fast and don’t cool them too far. Check the sugars as you drop the temperature to make sure nothing is going to spike or seems to be creeping in.”

There is still much research to be conducted on the disorder, admits Bethke. However, it hasn’t been difficult to keep the researcher focused on stem-end chip defect.

“From a research point of view, it’s a fascinating puzzle. You have a potato vine in a field. There’s an environmental stress, but there’s nothing apparent that tells you you’re going to have problems for potentially two months. Somehow, those potatoes remember that environmental stress, and after harvest, respond to whatever that stress was. What is the nature of the biochemical memory of environmental stress that gets you stem-end chip disorder? That’s an interesting question.”