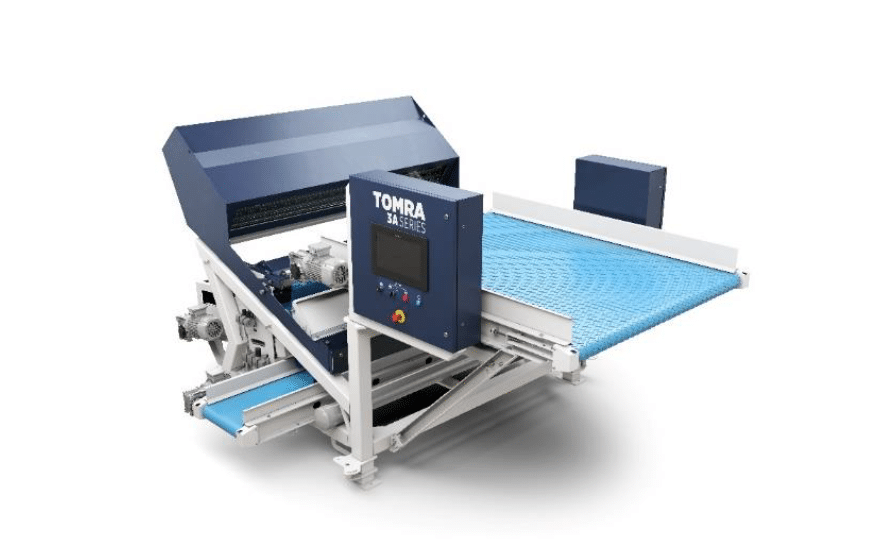

TOMRA Food has just introduced the TOMRA 3A, a vision sorter for the separation of a range of foreign material from unwashed potatoes. Developed in response to specific customer challenges, the TOMRA 3A delivers a new level of FM sorting performance but with added features.

The TOMRA 3A sorter can be positioned going into or coming out of storage, where it can reduce sorting labour and shipping costs, increase available storage space, and protects the stored potato and downstream equipment from damage.

The sorter employs an inspection and ejection system to detect and remove rocks, dirt clods and other debris from the incoming product. The TOMRA 3A is designed to operate at high capacity yet gently moves the product without risk of damage or bruising.

Jim Frost, product manager at TOMRA Food, said: “In developing this machine, we have learned from our experience working with potato growers and have adopted market-leading technologies already proven in some of our other sorting applications. As a result, this machine gives growers exactly what they’ve told us they want: greater capacity, green potato removal, no product bruising, greater durability and excellent reliability, ease of use, mobility, more data and statistics, and lower cost of ownership.”

Sophisticated Imaging Technology and More Automated Functions

Robust, state-of-the-art technology with high resolution cameras distinguishes between the crop and most commonly found foreign material types. Advanced software analysis separates dirt clods from dirt covered potatoes accurately. Additionally, TOMRA 3A can detect and reject gross green sun-exposed potatoes.

Time is precious during harvest. The TOMRA 3A optical system is mounted in a fully sealed camera enclosure and is designed to be resistant to rain, wind, dust and heat as well as potential vibration from moving the sorter between storage cellars. The TOMRA 3A performs well when pushed to meet the tight deadlines of a short harvest season. The TOMRA 3A boasts a 30 per cent increased capacity over previous TOMRA models of similar size. To accommodate customer’s needs, the sorter is available in three widths, allowing for throughputs from 100,000- 220,000 pounds per hour.

For ejection the TOMRA 3A sorter employs a highspeed finger-based ejection system. Designed for robustness and repeatability whether removing large or small objects, the ejection system features long life finger assemblies featuring a new quick “change out” design. Gentle potato handling continues to be a priority with this TOMRA sorter design and the new TOMRA 3A “accept” conveyor captures, decelerates and delivers bruise-free accept potatoes.

TOMRA ACT is an award-winning graphical user interface with many of the features of its big brother, the TOMRA 5A sorter. TOMRA is proud to announce that TOMRA 3A features the TOMRA ACT interface with simple to use and learn controls, including alarm reporting, statistics and diagnostics capabilities, with the option of remote support via a 4G modem connection. All this with a 15-in-wide (381-mm), high-resolution sunlight readable touchscreen.

With an all new camera sensor and LED technology, there are no moving parts in the camera or light bulbs to be replaced. The camera is mounted further away from the product sorting zone, greatly reducing the need for camera cleaning and calibration.

Frost also commented: “Real-world field validations of the TOMRA 3A with growers sorting fresh-pack and processed potatoes have proven the excellent capabilities and reliability of this machine. With the grower facing the growing issue of labour availability but even higher outputs and yields, automation is critical. We expect the TOMRA 3A to be popular with all potato growers and packhouses worldwide and to increase TOMRA’s presence in this sector in the United States.”

Potatoes are the leading vegetable crop consumed in the United States, and the TOMRA 3A will be of greatest value at farms sorting unwashed potatoes for seed, round and small table-stock, and chip-stock potatoes. Although not ready yet to handle all sizes of Russet, the TOMRA 3A is a valuable tool for sorting small to mid-size Russets where approximately 80 per cent of total foreign material is found.

The TOMRA 3A will be showcased for the first time in North America at Potato Expo 2020 in TOMRA Food booth #301, which takes place January 14-15, 2020, at the Mirage Event Center in Las Vegas, located within the Mirage Hotel and Casino.