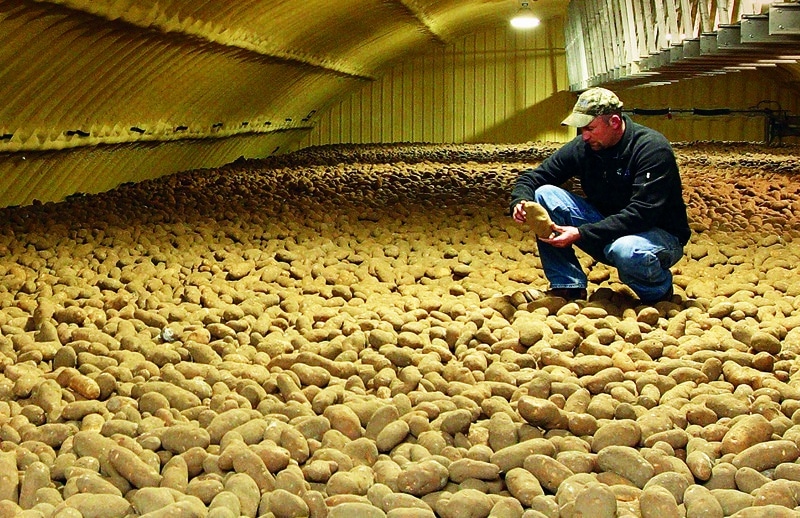

Storing your potatoes until shipping time can be just as important as the growing season is, which is why you need to keep spuds in the best possible condition from harvest to shed.

Experts

Editor’s note: This interview has been edited for length and clarity.

Spud Smart (SS): What storage problems could growers face this year based on growing season conditions?

Ron Howard (RH): We had hot, dry growing conditions on the southern Prairies of Western Canada towards the latter part of the growing season, which has stressed some of our potato crops and resulted in some disappointing yields. But most of the early maturing varieties have been dug and harvesting of the main crop varieties is just nicely underway. Quality has generally been average, but there have been reports of some abnormalities such as secondary sprouting, and knobbiness, which we usually associate with heat stress. Some of the extension specialists I’ve spoken to are concerned about the dry soil conditions that could result in lumps, and of course, that can lead to tuber bruising during digging and predispose them to dry rot and other infectious diseases which could show up in storage. In addition, if we’re bringing in warm tubers, they’re going to need to be cooled to remove that field heat.

Steven Johnson (SJ): I have a fear this year in the eastern part of Canada and Maine where I am, we’re going to not be able to supply enough humidity (in storage). This is reminiscent of 1995, when we had one of the driest years that I’ve been here for. We could not get enough humidity to suberize the potatoes and we had a lot of fusarium that came in because we could not get enough moisture into the air because it was so dry. Even soaking the concrete floors and adding humidity didn’t help. The potatoes came in so dry that they just couldn’t get moisture on them enough to suberize. They looked okay when they came in, but when the storage was opened, there was a lot of fusarium.

SS: Any harvest tips to help with storage?

RH: We want to make sure that we’ve desiccated our vines, which allows the skins to set up. Intact skins are a natural barrier to infection by pathogenic bacteria and fungi. We want to delay harvesting until that happens and until pulp temperatures have cooled down below, ideally between 7 to 18 C or 45 to 65 F. If the soil is dry and you have irrigation, I’d certainly recommend you consider a pre-harvest watering to minimize lumps. And fewer lumps of course will help avoid bruising the tubers during harvesting and subsequent handling both in and out of storage. We’d like to see potato storage is cleaned and disinfected as well as the diggers and handling equipment before they’re used.

As the tubers are coming into storage, we make sure we grade out any damaged, decaying tubers. That can be done sometimes in harvest or certainly prior to going into storage and that’ll reduce the load of inoculum.

Recently harvested tubers should be allowed to heal the wounds that build up that skin barrier… Keeping the tubers in storage about 12 C or 54 F for seven to 10 days will promote wound healing and then we want to drop the storage temperatures down, keep them as low as possible.

SS: What can you do to help potatoes in storage when you harvest them in cold and wet conditions?

RH: To manage chilling and freezing injury really starts in the spring with ensuring that you have properly formed hills that provides that insulating blanket to help protect the tubers from freezing if that’s a risk. Obviously, harvest your tubers before severe frost. If you’re digging in cold weather or trucking, you obviously need to protect the tubers against freezing and transit with tarps or enclosed trailers. If you’re digging chilled or slightly frozen tubers, it’s important that you wait until they’ve warmed up. If they’re dug cold, the bruising typically is a lot worse than if they’re allowed to warm up. Field frosted, chilled or wet tubers need to be held in storage for two to three weeks at warmer temperatures to allow for wound healing and to dry the surfaces down. And then of course, if there’s any tubers with visible breakdown, those need to be removed, graded out.

SJ: Run the fans continuously without humidity because if there are cool and wet conditions, there’s plenty of humidity in the mud with the potatoes and in the air. The curing temperature is right around what you’re bringing the potatoes to storage. So, at that point if you have air, bring it in. If it is very humid outside and you’ve managed to dry off some of the mud and soil that has come in with potatoes, it may be drier inside the building. And at that point, you may shut the building down so you’re not bringing in external air, you’re just moving air through there.

SS: Should air storage flow be set based on potato end use?

SJ: The different end uses require different amounts of air flow. I have some numbers down here. Seed at .8, table at .8 cubic feet per minute per hundred weight, french fries at one and chips at one and a half. I don’t think there’s any problem going higher than that. I think that probably most people would, if I was designing storage, I would design it for more than that airflow going through there. Simply because you can always back off that, but you can’t add more to it.

SS: How do you handle soft rot in storage?

SJ: If you’ve got a high percentage of soft rot loading or in early stages of storages, you’re looking for basically zero humidity and lots of air… We don’t have information to support the use of bactericides in ventilation. We can’t seem to get these materials to show anything through the humidification system. So, I don’t recommend it.

We will use hotspot fans. We will put fans with tarps over. There may be a load that got rained on, you thought you might get away with it. Those are fairly easy to target either by looking at the pile or with an infrared temperature gun or hotspot fans, about a one-third horsepower fan. I generally like an inner tube or a tarp around to the fan and it does a pretty good job, but it’s going to be on there for a good three weeks or more.

SS: How do you handle pink rot in storage?

SJ: The best thing to do with pink rot in fields is delay harvest, let the potatoes rot in the field. When pink rot is brought in, the potatoes are going to be splattering all over the lags. Cure the potatoes cooler than you want them, but not cold. And if they’re quite bad, rapid cooling may be warranted. Really bring the temperature down fast. However, if these are going into the table stock market, the tuber should be warmed up for at least a day and a half to two days before they’re put in the bag, because they may have some breakdown and it’s better to pull rotting potatoes out on the packing line then have them go into plastic bags.

SS: Where should sensors be placed in storage?

SJ: Despite where they’re placed in the storage, and they’re often placed there by the storage construction and not necessarily placed by a storage manager, I like them in the plenum. Not necessarily by the fans or where the humidity is introduced. Usually sensors are placed in the middle of a plenum, or the far end, away from the fan.

For more information on potato storage watch our latest webinar about it.