Though it’s prime barbeque and beach season, harvest and storage are just around the corner. Are you prepared? Here are quick reminders that might just save you hassle (and dollars, too):

- Calibrate your machinery now. Even seasoned pros often sheepishly tell me the only time their storage bin sensors were calibrated was when they were installed. If you’re one of the lucky few, your un-calibrated equipment might stay in operating shape from year to year. If you’re very unlucky, it might read drastically wrong, setting your bin up for a storage nightmare (I can tell you horror stories). Most uncalibrated sensors, however, will fall somewhere in between those two extremes. They could be functioning but costing opportunity and premiums.

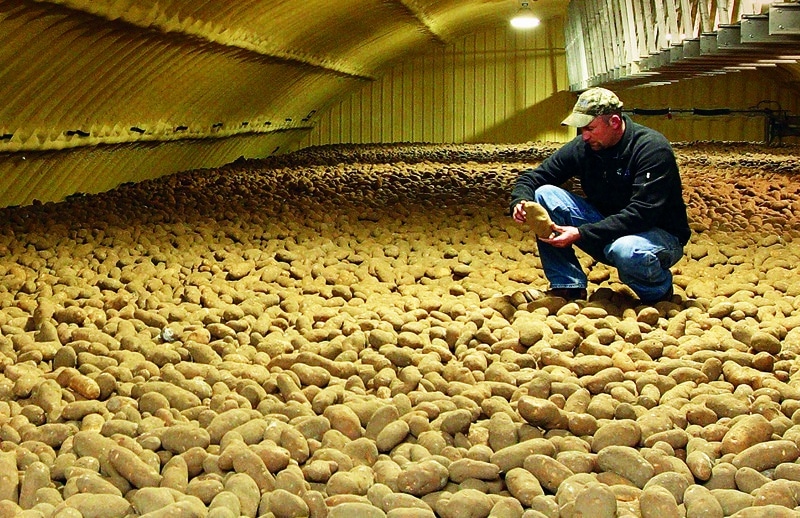

- Get bins clean now. Growers clean storages every month of the year, but now’s a good time for that final round of cleaning and disinfecting. Yes, you could wait to complete the last details of cleaning until this year’s spuds are literally on route to the bin, but why add that unnecessary time pressure at the busiest time of year?

- Double check storage infrastructure. Storages can take an unintentional beating from the many pieces of equipment and heavy loads of potatoes that fill them year after year. A quick but intentional check including ducts and flumes, safety hazards like cutting/tripping hazards, even seemingly insignificant details like lightbulbs can contribute to keeping load-in moving smoothly at go-time. Also double check that your humidification systems are in good working order, making sure to clean up cell deck and hard water build up.

- Invest in expertise where necessary. Don’t have the knowledge, time or desire to prep your storage to the level your potatoes deserve? Hire now. I chatted with a farmer not many months ago who delayed hiring a storage consultant last year until it was too late. He told me that he spent all winter fighting preventable issues because his HVAC system wasn’t optimized. It’s a long, long storage season to battle unnecessary problems.

- Pre-buy product and have a fully considered application plan from each individual bin’s first day of storage. If you’ve got, say, a half dozen storages to load at five-ish days per loading, your first stored spuds will sit for a full month before your last tubers are in. That first month of storage is the most critical storage month of all, and products exist to support the bin through this stage. Applying 1,4SIGHT right at bin close-up, whether or not you plan to follow with CIPC, can dramatically improve tubers’ settling and decrease moisture loss through early storage.

- Have a plan for optimal temp and humidity. Is your water access in working condition to wet down your storage floor? Is your air conditioner functional and ready to help cool hot spuds if necessary? Your ability to support tubers through their earliest storage days – to adequately cool them without dehydrating them, and to adequately moisten them without causing sweat – will make or break your storage season.

Good luck and good harvesting!