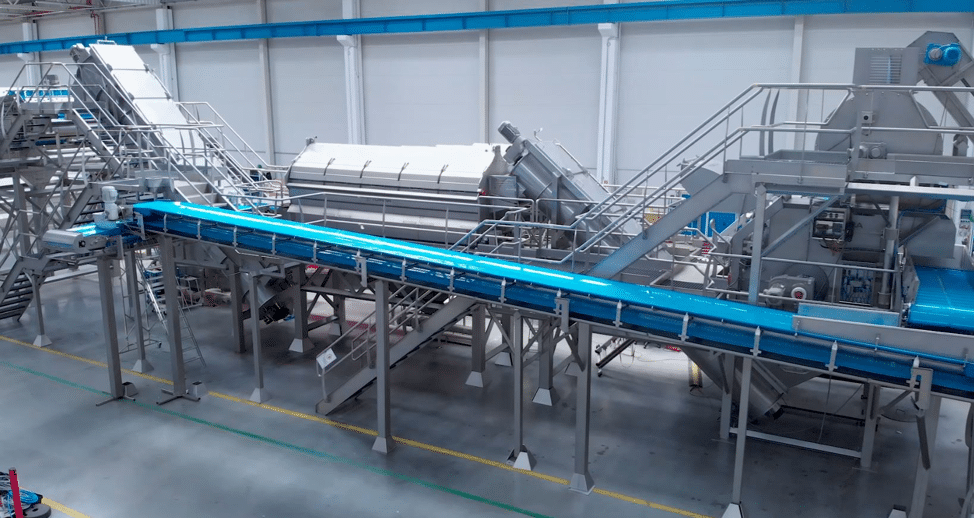

Cavendish Farms, one of the largest processors of frozen potato products in North America, is equipping its new, state-of-the-art production facility in Lethbridge, Alta., with TOMRA’s Eco steam peelers.

Cavendish Farms is committed to sustaining the environment and operates at the highest standards to protect the environment.

“We are continuously looking for new ways to reduce our carbon footprint and increase our processing efficiency. To equip our new, state-of-the-art production facility in Lethbridge, we partnered with TOMRA Food,” said Andrew Macleod, Lethbridge project lead at Cavendish Farms.

Cavendish Farms has existing solutions supplied by TOMRA at their processing facilities in New Annan, P.E.I., and Jamestown, N.D. The new production facility will include the latest steam peeling technology from TOMRA.

“Steam peeling has for a long time been the most efficient method of removing skin from the surface of vegetables. TOMRA’s Eco steam peeler is not only the fastest steam peeler; it is also the most efficient in the industry, using 28 per cent less steam than other peelers of its type,” said Eamonn Cullen, market unit manager peeling at TOMRA Food.

“We were the first to introduce high pressure steam peeling to the vegetable processing industry and we continue to invent technologies to improve steam peeling performance. The Eco steam peeler enables processors to reduce the energy consumed in the process to levels not seen in the industry before,” he says.

“At Cavendish Farms, we pride ourselves on high-quality products and exceeding our customers’ expectations. We are a family food company that puts pride, dedication and a whole lot of know-how into everything we grow, and everything we make. By partnering with TOMRA Food, we expect to achieve significant savings in energy costs and raw materials to produce the highest quality frozen potato products,” adds Macleod.