Category — Equipment

AgroScout

Commercial Launch: March 2021

AgroScout is a digital, drone-based scouting program which monitors potato fields from the leaf up. It integrates images gathered by drones, satellite and mobile phones, providing a range of services from planting to harvest to help growers reduce chemical inputs, improve productivity, and save money. AgroScout’s services include early detection of pests and disease, plant stand count, growth monitoring, and nutrition and irrigation evaluation.

The AgroScout platform uses affordable, off-the-shelf drones to scout the fields and take high-resolution, geotagged images. The drone scouting, along with satellite and mobile phone imagery allows growers to cover 100 to 1,000 times more field area than regular scouting alone.

The AgroScout android-based sky application creates flight patterns to maximize field coverage. The drones fly as low as two metres above canopy, maintaining a consistent level regardless of terrain contour changes. Captured images are run through AgroScout’s AI algorithm to identify the 12 main common pests and lesions among potato crops and across all growth cycles.

AutoPath, John Deere

Commercial Launch: November 2021

AutoPath is a guidance system that automatically creates full-field guidance lines based on the location of planted rows, reducing setup time in the field. Regardless of equipment width, growers are able to easily identify the correct rows for each pass, whether that be the hiller, sprayer or harvester. AutoPath integrates active implement guidance technology currently found on GPS steering system in potato planters.

The AutoPath system is easy to use. Operators need only drive to the line and hit AutoTrac resume. It can also be combined with a variety locator map on-screen to prevent mixing two neighbouring varieties in the field.

AutoPath is part of John Deere’s Gen4 Automation 4.0 display bundle and can be added to many existing John Deere machines.

LDN Wide Spray Bubbler, Senninger Irrigation

Commercial Launch: August 2021

The LDN Wide Spray Bubbler is a low energy precision application (LEPA) nozzle for mechanical move irrigation systems. It has the low-pressure water-saving efficiencies of a LEPA application but still provides total coverage.

It produces a wide gentle aerated pattern suitable for most crops and soils. Growers can also change from a LEPA to LESA spray pattern by twisting and flipping the deflector assembly.

8312 potato planter, Spudnik Equipment

Commercial Launch: 2019

Spudnik’s 8312 12-row potato planter can fold up to the width of a six-row, enabling it to be moved from field to field easier.

The six-row base has two three-row wings on either side that can swing up when required. This allows it to more easily traverse roads and bridges and conform to size restrictions while travelling from field to field.

The 8312 makes it easier job to navigate around power poles and irrigation equipment. It also cuts down on the amount of equipment — or people — that’s required to plant potatoes.

Rite Weight, Greentronics

Commercial Launch: 2020

Before potato seed hits the field, it needs a seed treatment, but setting the application rate to evenly coat potato seed isn’t easy. This is where Rite Weight from Greentronics comes into play.

By installing the Rite Weight scale on the conveyor ahead of the treater, it can output a signal proportional to the flow rate over the scale. With this connected, the pump will apply chemical according to the flow rate measured by the scale. It offers greater uniformity in chemical application and reduced waste/cost.

The scale can also be used during the fall to apply storage chemicals. It can help with inventory tracking, field and variety totals recording, and mapping of storages.

Soiltech Wireless sensor

Commercial Launch: 2020

The Soiltech Wireless sensor is a soil moisture sensor. It’s a yellow device that’s buried under the soil at the start of the growing season with the logo facing towards the sky. It has a moisture, temperature, humidity, GPS and bruising sensors on it — the sensors are located in the silver bands surrounding the device.

Throughout the growing season, the Soiltech sensor sends data back to a phone application over a low power cellular data called LTE Cat-M1 and NB-IoT — which can operate at significant distances from cellphone towers. By being able to send information to a phone application, it saves growers from having to drive and check fields individually.

At the end of the season, the device is harvested with the rest of the potato crop and goes into storage to monitor it until shipped. If it’s “planted” in a non-potato field, the Soiltech sensor can be dug up before or after harvest. It holds a charge throughout the season and needs to be recharged annually, with a full charge taking 12 hours to complete.

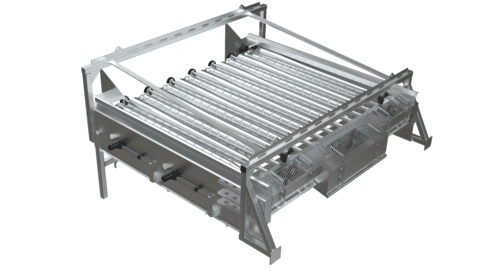

Vertical Adjustable Roll Sizer, Southern Fabrication Works

Commercial Launch: March 2021

The vertical adjustable roll sizer from Southern Fabrication Works is an evolution from the traditional tapered roll sizers. It’s built to food safety standards with stainless-steel. The vertical adjustable roll sizer is designed and made for 24/7 work with industrial engineered components.

Traditional whole potato sizers can be large with costly maintenance and roll sizer adjustments which take time. The vertical adjustable roll sizer can process larger volumes of potatoes, is smaller than other machines, requires less maintenance, can be adjusted on the fly and holds up to six pre-set profile settings controlled by the push of a button.